We have reached December and time for the topic of the Equipment Highlight to change as well. This month we look at equipment used in the produce industry, starting with onions.

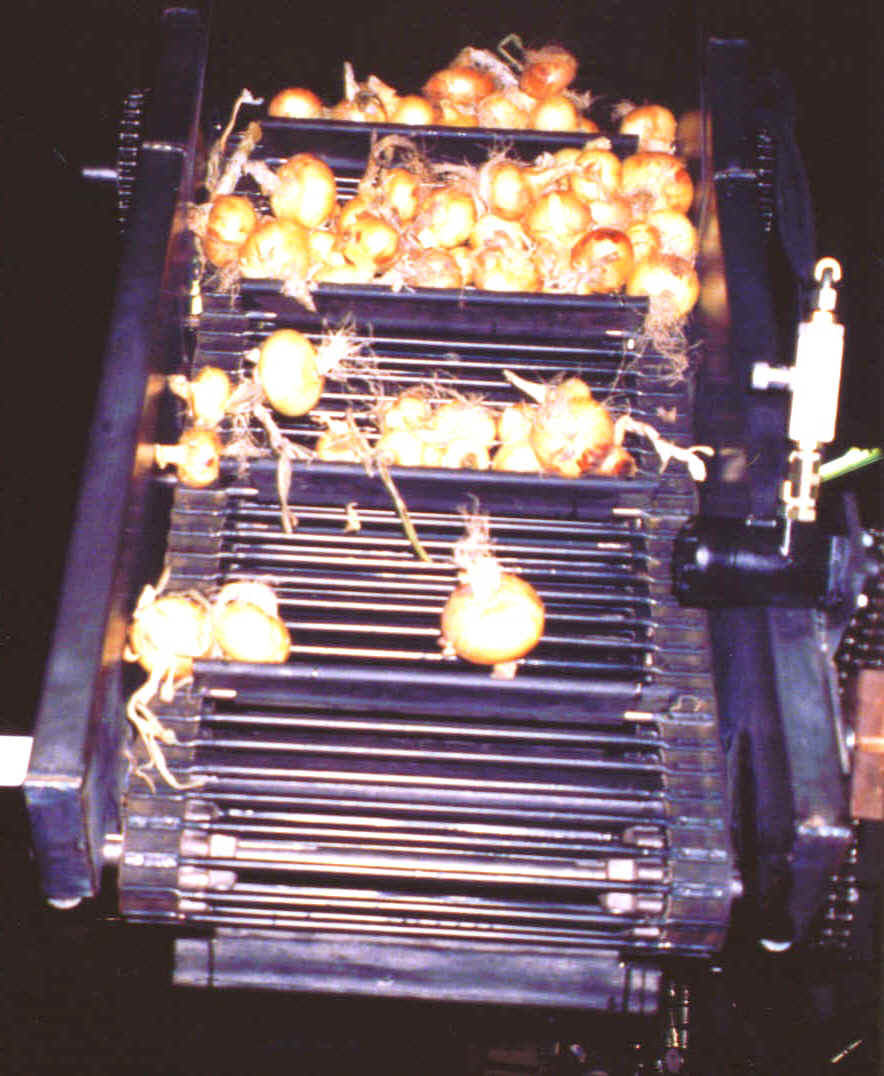

Nicholson Onion Top Tail Remover – Finish Topper

The Nicholson Top Tailer has been developed to meet the exacting demands of retail outlets requiring high quality display crops without damage. By using a unique twisted stainless steel shaft rotating against smooth faced, spring- loaded polypropylene rollers, the cut is made without pressure on the neck. The spirals run crossways to the crop flow and have right and left twists to ensure rotational movement of the onion. This continuous smooth flow without oscillation or vibration minimises crop damage. The Top Tailer can be used on the onion straight from store or as finishing machine before packing the onion. The machine will top and tail down to 30mm, so pre-grading is not necessary. A 1.2m infeed conveyor is supplied as standard, longer options are available. To maintain absolute control across a wide range of conditions and flow, the bed is split into separate drives with variable speed to each set of rollers. Rams are fitted to vary the pitch of the bed at the discharge end.

Compared to traditional labor intensive systems, the NicholsonTop Tail produces a more consistent finish, with low levels of damage to the crop.

Nicholson Onion Field Topper

The Nicholson Onion Field Topper is a fast, efficient method of topping the onion without creating mulch or staining, even when working with green onion tops. It has enough suction to lift layed over onion tops. The clean cut seals quickly. The onion topper’s high inlet with manual or automatic height adjustment accepts standing onion tops while maintaining high ground speeds. Cut onion tops and debris is delivered into the wheel tracks. There is a choice of 1, 2 and 3 row onion field toppers.

Available for 60″, 68″, 72″, 80″ and 88″ row design.

Features:

- Quick, clean cut; not shredded.

- 2 Stage cutting and discharge reduces mulching and staining.

- Suitable for green tops.

- Better presentation for tops into the wheel tracks.

- High inlet to accept a standing crop.

- Manual or Auto height adjustment.

- High ground speed.

- HP requirements : 80 HP for a single row : 135 HP for 3 row.

Nicholson Onion Harvester

The Onion Harvester is a purpose designed and engineered alternative to the commonly used converted potato harvesters whose webs are too steep and cleaning systems too aggressive for easily damaged onions. Operating capacity is around 60 tons/hour.

Harvesting onions, particularly a sweet onion, is an area where damage can be reduced. Most onion harvesters are too steep creating rollback, unsuitable cleaning devices creating skinning or bruising, cart elevator too narrow so must run at high speed creating damage in the trailer.

The Nicholson Onion Harvester has been specifically built to overcome these problems, at a reasonable cost. The Nicholson Onion Harvester gently lifts the onion from the field, ideally from atop the windrow bed contrived by the Nicholson Onion Raiser. The onion is then carried across a cushioned web leaving the small unmarketable onion in the field. Next the onion is advanced to the mechanically controlled elevator and gently delivered to the trailer.

Features:

- Auto depth control

- Self leveling

- Self steering

- Mechanically folding elevator

ONION HARVESTER EQUIPMENT

HYDRAULIC VARIABLE CUTTER BLADE REMOTE ADJUSTMENT, VARIABLE RPM FAN, HYDRAULIC BLADE DEPTH, VARIABLE BED SPEED, 2 PIVOT BOOM, AND POWER STEERING

ALL HYDRAULIC OPERATION WITH REMOTE CONTROL PANEL

ELECTRIC OVER HYDRAULIC VALVE OPERATION

CATALOG REF# 03053ONI01

Complete Processing Line For Onion

Line shown: suitable for onions and all

Unwashed products like potatoes and red beet.

Estimated capacity type A3 (tons/hour).

Onions: 15

Set onions: 7

All capacities are indications are based on experience from the past and depend on soil and product conditions,

AUTOMATIC ONION PEELER

With this unique machine picking, singulating and positioning are done automatically. This machine offers a capacity of 100 onions per minute. High technology onion processing equipment.

> perfect peeling quality; very clean topping and tailing by means of rotating knives

> high yield (reduced waste)

> knives with extended life-spa

| Voltage: | 230/400 V, 3 phase, 50/60 Hz |

| Total installed power: | 4.8 kW |

| Air pressure: | 6 bar (dry air) (87 psi) |

| Air consumption: | approx. 1,2 Nm3/min. (42 cfm) |

| Weight: | ± 900 kg (1,980 lbs) |

| Dimensions (L x W x H): | ± 6.100 mm x 1.150 mm x 1.750 mm – ± 2.335 mm (240″ x 45″ x 69″ – ± 92″) |